Pump Station Controls

As pump station experts, Engineered Pump is well positioned in pump station control panel equipment selection, supply and troubleshooting. We supply at all levels from small residential single-family dwelling to large communities and even entire towns. For these reasons we have a unique perspective and can work with any control device from a simple manual starter and a float switch to the most complex multiple level input (float, pressure transducer, ultrasonic transducer, radar, differential air pressure, etc.) We can overlap the technologies on each and produce hybrid controls that can designed to suit the individual clients’ needs.

Residential Pump Station Control

Specific to the needs of the homeowner, we stock and supply simplex and duplex panels, indoor and outdoor feature rich with embedded controls and solid-state circuitry. As a standard we have pump run indication, pump hand – off – auto toggle switches, pump breaker disconnects, float level indication, alarm contacts for both building security input (if used) or 12vDC for a lobby alarm. These panels are manufactured by either Northwest Tech Con Systems Ltd (NWTC) or SJE Rhombus.

Onsite Septic and Effluent Pump Station Control

Specific to the needs to onsite septic disposal, we stock and supply simplex and duplex septic and effluent control panels with both timed dosage and demand dosage available. All panels are feature rich with embedded controls and solid-state circuitry. As a standard we have pump run indication, pump hand – off – auto toggle switches, pump breaker disconnects, float level indication, alarm contacts for both building security input (if used) or 12vDC for a lobby alarm. These panels are manufactured by either Northwest Tech Con Systems Ltd (NWTC) or SJE Rhombus

Commercial Pump Station Control

With a clear understanding of the specific requirements in Commercial applications, we stock and supply products from NWTC, SJE Rhombus, Primex (a subsidiary of SJE Rhombus) and Tulsar Canada Ltd. These pump station controls are meant to work in a hard duty environment and conform to all current regulations including intrinsically safe for class 1 hazard locations as found in commercial wastewater applications (storm, sanitary, parking, elevator sumps). There is a mix of types of controls available.

Solid State: The controller utilizes micro relays, and sometimes computer chips, permanently mounted on an electronic board to control the pumps.

Hard Relay: The controller generally will consist of several electro/mechanical relays, which are activated by the sensing devices to control the pumps.

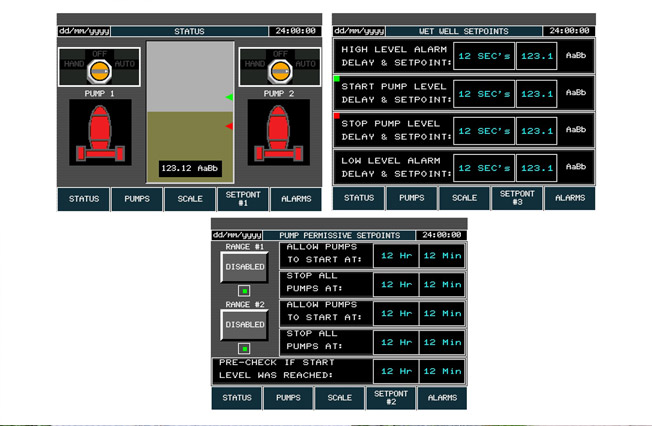

PLC: All of the logic (operation) for the pump station is programmed into the PLC and the PLC responds to input signals to activate the pumps.

PLC/HMI: Generally, they are set up with a set program sequence to activate pumps where the operator can alter some of the programming and input the working parameters and be able to retrieve data. In some cases that have communications available for a light version of SCADA. The programming embedded is pump intuitive and makes for a higher level of interactions without having to have the specific training necessary to make normal PLC adjustments, all of the above to meet with the site’s specification.

Municipal and Industrial Pump Station Control

Recognizing the unique nature of Municipal and Industrial Pump Station Control we have built to specification panels manufactured by Tulsar Canada Ltd. and Primex (a subsidiary of SJE Rhombus). We can build to suit the end clients’ requirements or help design based on the client’s process requirements utilizing our recognized brand of controls or working with the end user’s requirements for specific brand controls.

Specialized and Custom Pump Station Control

With our available pump station, process, and treatment expertise we are able to custom build pump station control panels to meet many specialized requirements. Examples:

Store and forward. Many existing older sanitary and storm water gravity mains and force mains are at full capacity. With sanitary, we design to optimize the system and pump when others are not, allowing development in areas that would otherwise be unserviceable. We use large holding tanks, mixing as necessary, and discharging at specific flow rates at night while the gravity and force mains are not in full usage.

Pump Station Control (KIOSK)

Our unique history allows us to participate in the design and construction of large and small Pump Station Control Kiosks. We are utilizing the manufacturing facilities of Primex (a subsidiary of SJE Rhombus) and Tulsar Canada Ltd. to produce high quality pump station control kiosks. Our 40 + year history of supplying not only the pump station and controls but the kiosk with Hydro service entrance and standby generator gives us a unique perspective and insight into the issues that connect them.

Why Engineered Pump?

One company accountability with pump stations expertise to reduce project risk and give you peace of mind!